CO2 Extractors – definition of profitable business areas

Comprehensive Research on Launching a Business in the Field of Supercritical CO₂ Extraction

Research Overview

This analytical report is designed for entrepreneurs and investors considering the launch of a highly profitable business based on cutting-edge supercritical CO₂ extraction technologies. We provide an in-depth analysis of the market, financial prospects, and technological solutions, enabling you to make informed investment decisions and efficiently enter promising market niches.

Key Benefits of the Research

- Economic Expertise and Profitability Analysis

Detailed financial models, including calculations of economic efficiency, ROI, payback period estimates, and potential project scaling scenarios. - Up-to-date Equipment Market Overview

An updated database of suppliers and technological solutions — a comparative analysis of prices, technical specifications, and reliability of leading CO₂ extractor manufacturers across various capacities. - Industrial Data on Extract Yields

Comparative tables of active ingredient extraction from different raw materials, meeting modern standards of product quality and standardization. - Calculation of Production Capacity and Costs

Comprehensive modeling of resource and capital expenditures: energy efficiency, CO₂ consumption, raw material costs, optimization of personnel and operational expenses. - Identification of Relevant Market Segments

SWOT analysis of promising markets, strategic recommendations for entering high-yield segments, and risk assessment to minimize inefficient investments.

Why Invest in This Research

- Access to Expert Data and Best Practices

Save resources by leveraging systematized analytical materials prepared by industry experts. - Minimization of Investment and Operational Risks

Objective analytics help you avoid critical mistakes during the planning and launch stages. - Practical Tools for Business Scaling

Receive a decision-making roadmap: step-by-step instructions for selecting optimal equipment, building efficient production processes, and entering strategically important markets. - A Strong Competitive Position

Based on this research, you will be able to develop an effective business strategy and ensure sustainable project profitability in line with real market trends.

Invest in professional analytics and accelerate your journey from concept to profitable business! Request your copy of the research and create a competitive, innovative, and eco-friendly business today!

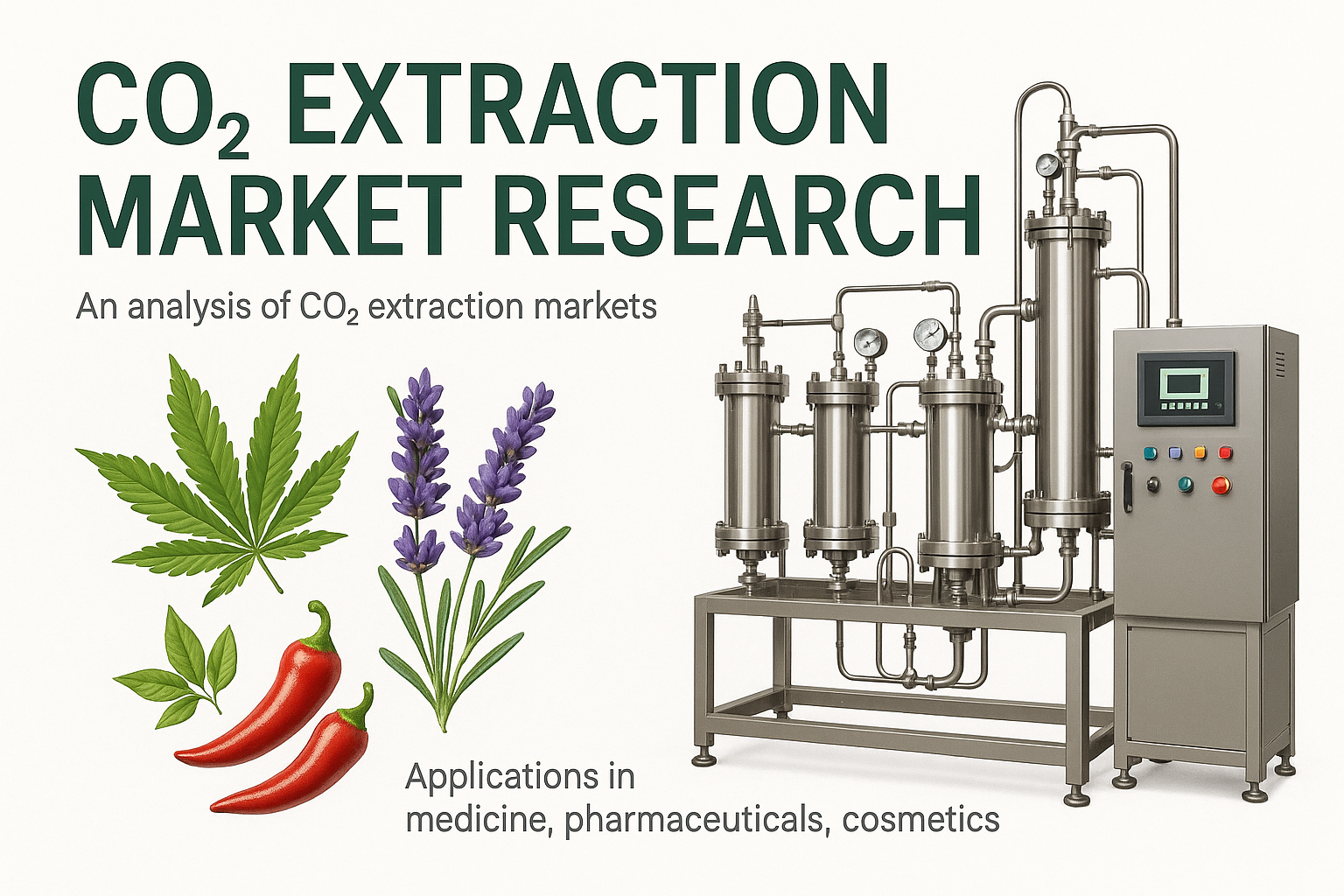

About CO₂ Extraction

CO₂ extraction is a modern method for obtaining extracts from plant (or other natural) raw materials using carbon dioxide (CO₂) in its liquid or supercritical state.

- In the CO₂ extraction process, carbon dioxide acts as a solvent that can efficiently extract fat-soluble, volatile, and other bioactive substances without the use of organic solvents or high temperatures. There are two main modes:

- Subcritical extraction (low temperature and pressure): liquid CO₂ is used.

- Supercritical extraction (above the critical point of 31.1°C and 73.8 atm): CO₂ acquires the properties of both a liquid and a gas, allowing it to deeply penetrate the raw material and effectively dissolve target components.

- After extraction is complete, CO₂ evaporates without leaving any residue in the product. As a result, the extracts are highly pure, free from solvent residues, and retain all the beneficial properties of the source material.

- Compared to traditional methods (using alcohol, hexane, etc.), CO₂ extraction:

- Preserves a wide range of heat-sensitive biologically active substances.

- Leaves no toxic solvent residues.

- Allows adjustment of yield and product purity simply by changing temperature and pressure parameters.

- Main applications: food, cosmetics, pharmaceutical industries, and the production of essential oils and extracts.

Key advantages of CO₂ extraction:

- High purity of the final product.

- Environmental friendliness and safety.

- Selectivity of the extract’s composition.

- The possibility to reuse CO₂ multiple times.

Unlike most solvents, CO₂ is completely removed from the extract at the end of the process, which makes this technology especially valuable for producing natural and pure products.